Aerosol Fire Suppression System

Aerosol fire suppression systems provide very effective and eco-friendly fire suppression for fires in enclosed facilities and local areas. The aerosol system uses particles that spread directly to the area in a few seconds to regulate and avoid fire damage. We are providing supply and installation of aerosol fire suppression systems in Dubai. We are also an authorized distributor of aerosol fire suppression systems. For more details and to get the best price please contact us or send an enquiry to info@blueflamedubai.com

what is an aerosol fire suppression systems?

Condensed aerosol fire suppression is a particle-based form of fire extinction similar to gaseous fire suppression or dry chemical fire extinction. As a result They are cooled and “condensed” within the device and discharged as solid particles which is one of the best fire fighting system where used for costly device protection

Aerosol fire suppression systems in Dubai, which is specifically designed for professionals who need effective and economical special hazard fire suppression.aerosol technology delivers up to 35% savings in equipment and life cycle cost felt over traditional systems such as FM 200 system and NOVEC 1230 system. Blueflame fire fighting provide design and installation of these systems in Dubai and other emirates of UAE. we have installed FM 200 fire suppression systems in African countries also.

Application of Aerosol Systems in Dubai

- Gas turbine enclosures Generator rooms

- Switch gear rooms

- Battery rooms (lead acid / lithium ion)

- Wind turbine nacelles and power rooms

- Electric machine rooms

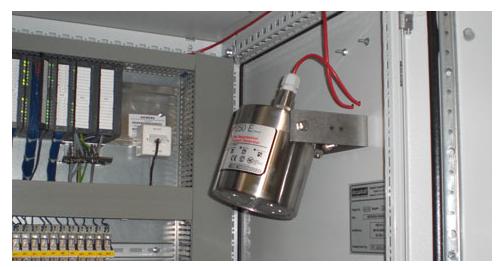

- Cable trays and electric cabinets

- Bus passenger compartments

- Lifting equipment

- Specialty vehicles

- Battery compartments (lead acid)

- Power generation buildings

- Motor control centers

- Off-road vehicles engine compartments

- Tunneling equipment.

These are the areas where aerosol systems can be used effectively and economically.

What are the advantages of aerosol systems ?

- there is no distribution piping, manifold,

or nozzles. - No floor space requirement or

shoring up for weight. - no need of special handling for compressed

gas cylinders. - Not having venting or ceiling tile clips for discharge forces.

- have no solenoid actuators, control heads, or hoses.

- No water drains or pipe freeze protection.

- Not having system pressurization or room integrity tests.